Sdc630 Workshop Manual Band

Package Size 3.00cm * 2.00cm * 1.00cm Package Gross Weight 1900.000kg Advantage 1. Certificate:We provide CE and ISO cer

Description

Basic Info.

| Model NO. | SDC630 |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008, QS, GMP |

| Customized | Customized |

| Condition | New |

| After-sales Service | Free Parts |

| Technical Service | Yes |

| Operational Video | Yes |

| Free Parts | Yes |

| Weight | 1900kg |

| Product Application Field | Elbow/Wyes/Tee/Cross |

| All The Models | 315mm 630mm 800mm 1000mm 1200mm |

| Delivery Time | 15 Days |

| Warranty Period | 2 Years |

| Feed Speed | Adjustable |

| Lins Speed | 0-250m/Min |

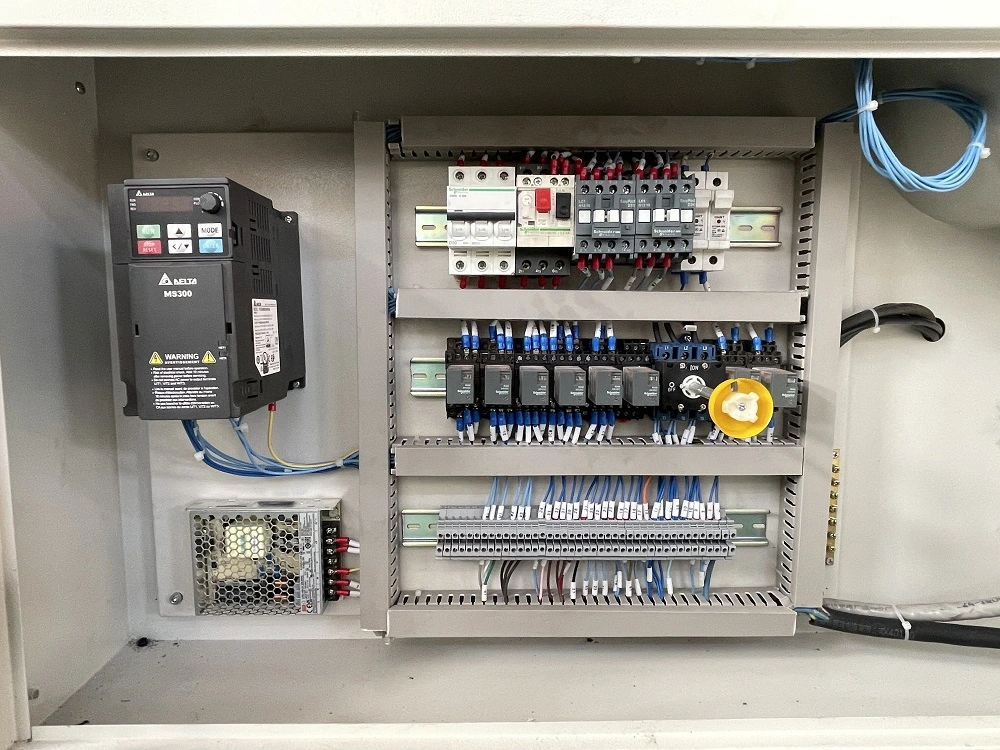

| Total Power | 3.7kw |

| Working Voltage | 380V 50Hz |

| Cutting Angle | 0-67.5 Degree |

| Cutting Angle Error | 1 Degree |

| Welding Range | 630mm |

| Transport Package | Wooden Box |

| Specification | SDC630 |

| Trademark | SUDA |

| Origin | China(Mainland) |

| HS Code | 85152900 |

| Production Capacity | 500/Year |

Packaging & Delivery

Package Size 3.00cm * 2.00cm * 1.00cm Package Gross Weight 1900.000kgProduct Description

Advantage

1. Certificate:We provide CE and ISO certification and official test reports for each machine.2. Guarrantee Period: 16-24 months free warranty,life Time Guarrantee.3. Voltage: 220v or 380v is normal voltage, can customized 110v, 240v, 415v, 440v or according requirements.4. Mode of transportation: Mostly by ship, less than 100kg, recommended by air or express.We can also cooperate with the shipping companies that they can help finish the custom clearance, even if you do not have import rights, you can buy.5. Delivery time: 1~5sets: 2~3workdays; 6~10sets: 5~7workdays; Above10sets: 8~10workdays, by the way, we have stocks for many products, these products can usually be delivered within 24~48 hours. 6. Free Spare Parts: 1pc metal tool box, 1pc temperature sensor, 1pc screw driver, 1pc spanner, 2pcs blades, 2pcs fasten screws.7. Electronic accessory:Electronic accessory of well-known brands will ensure the reliability of the machine. More importantly, if you need urgent repairs, you can buy these accessories faster in the local.

USES and features:

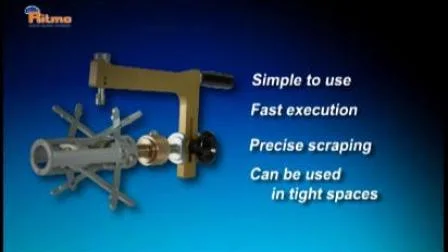

1. Suitable for cutting pipes according to specified angel and dimension while making an elbow, tee or cross, which lowest the material waste and improve the welding efficiency.

2. Cutting angle 0~67.5° accurate angle location.

3.Applied to solid pipes or structured wall pipes made of thermoplastic such as PE and PP, and also other pipe and fittings made of non-metal materials.

4.Self inspection and stop of the machine in case of saw blade breaks enables to guarantee operator's safety.

5.Reliable, lower noisy, easy to handle.

Specification

| Model | SDC630 |

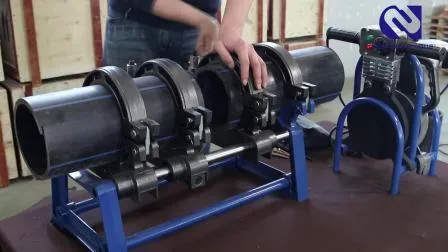

| Welding Range(mm) | ≤630mm |

| Cutting Angle | 0-67.5° |

| Cutting Angle Error | ≤1° |

| Lind Speed | 0-255m/min |

| Feed Speed | Adjustable |

| Working Voltage | 380V 50Hz |

| Total Power | 3.7KW |

| Weight | 1900KG |

==>>Operating procedures

==>>Delivery process

SUDA PLASTIC PIPE MACHINERY CO.,LTD. Is a professional manufacturer in China. Years of experience in producing and research, we can supply the best quality machines to all the customers. Our products including: Hydraulic Butt Fusion Machines, Manual Butt Fusion Machines, Workshop Fitting Machines, Workshop Cutting Machines, Electrofusion Machine, HDPE Fittings, Electrofusion Fittings, Plastic Sheet Butt Welding/Rolling/Bending Machines Etc. Customers' biggest benefit is our goal, machine's quality is the life of our company. Many years of growth, we have our best partners in the world. We have the certificate of ISO and CE approval. This ensures our machines have the highest quality, best service and reliable warranty. We have the concept of "Customers First, Quality Foremost", we sincerely welcome all friends visit and co-operation.

Our Advantages1.The main accessories of the welding machine are made by fully automatic aluminum casting. It is lighter, more solid and smooth than the machine made by sand-casting and steel-form technology.2.Using static plastic-spraying process, colorful,smooth surface and not easy to be damaged.3.The main accessories of the hydraulic station are imported overseas, which could reduces the maintence and extends the life of hydraulic station.4.The package we use is fumigated cartons which has nice appearance and solid structure for convenient trasportation.

Our Contact

Send now