Automatic Pipe Flange Welding Weld Machine Equipment Internal External Longitudinal Circumferential Seam

Package Size 2300.00cm * 900.00cm * 500.00cm Package Gross Weight 5000.000kg A. Usage and Application of Specialized Wel

Description

Basic Info.

| Model NO. | LHD Series |

| Frequency Range | Custom Made |

| Electric Current | Custom Made |

| Welding Function Cell | Welding Torch Position Control, Swing |

| Welding Style | Automatic Continuous and Tack Welding |

| Mechanical Frame | All Kinds of: Stationary or Moving Gantry, Special |

| Workpiece Fixture | Welding Roller Bed, Bracket, Special Design |

| Workpiece | Pipe, Flange, Elbow, Girber Beam |

| Welding Position | Internal and External Welding |

| Welding Technology | Back Welding, Finished Welding, Strip Cladding |

| Welding Seam | Longitudinal and Circumferential Welding |

| Welding Mode | Saw, Gmaw, Built up Welding |

| Transport Package | Disassembled and Packed |

| Specification | For pipes from diameter 150mm to 2000mm |

| Trademark | Wuxi JACK and AMASS |

| Origin | Wuxi, China |

Packaging & Delivery

Package Size 2300.00cm * 900.00cm * 500.00cm Package Gross Weight 5000.000kgProduct Description

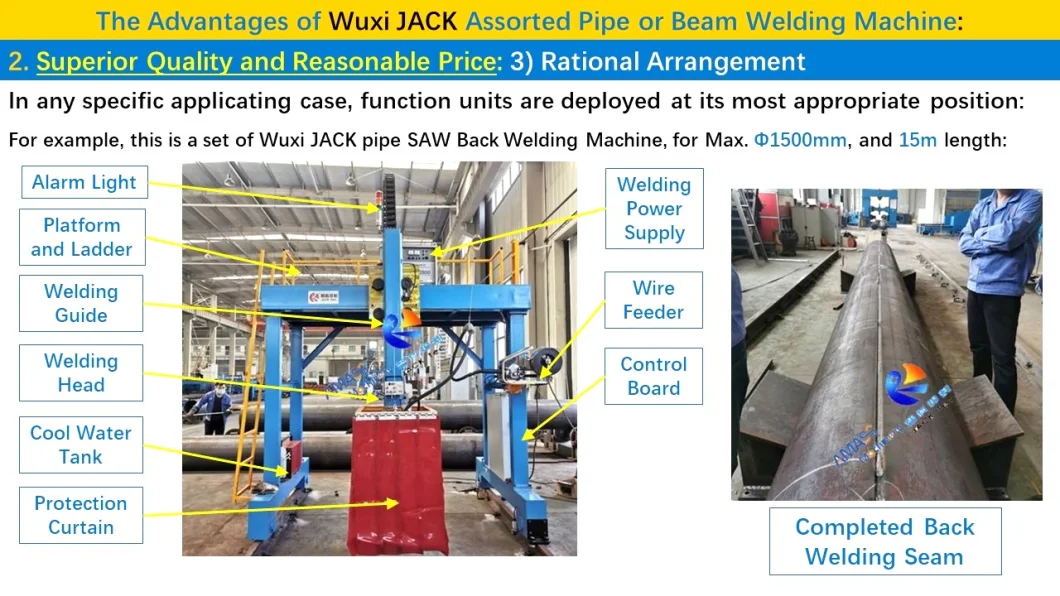

A. Usage and Application of Specialized Welding Machine: Automatic Specialized Welding Machine includes equipment group for:1. Workpiece: Pipe, pipe flange, pipe elbow, structure member, girder, any other special workpieces;2. Welding Seam: Internal / external circumferential or longitudinal seam, in the form of continuous or tack welding;3. Welding Technology: Back welding, finished welding, built-up welding, etc.;4. Welding Mode: SAW, GMAW, TIG, MIG, etc.5. Workpiece Size: Pipe Diameter: Φ100mm ~ Φ1500mm; Girder 2.4m x 2.4m x 49m; Any special sizeIn general, these automatic Specialized Welding Machine are special designed and produced based on customer demand.B. Advantages of Wuxi JACK (Wuxi AMASS) Specialized Welding Machine:This is superior product of Wuxi JACK (Wuxi AMASS). Below slides give graphical introduction on our strong points:

C. Technical Brief and Parameters: 1. LHD1500 Box Gantry Moving Pipe Back Welding Machine: (Fig.1)Usage: For longitudinal seam CO2 Back Welding:

| LHD1500 Automatic Pipe Back Welding Machine | |

| Welding Pipe Diameter | 500 ~ 1500 mm |

| Welding Pipe Length | 6 ~ 12 m |

| Welding Pipe Thickness | 12 ~ 25.4 mm |

| Gantry Frame Traveling Rail Span | 2500 mm |

| Gantry Frame Traveling Rail Length | 15 m |

| CO2 Back Welding Speed | 240 ~ 2400 mm/min. |

| Welding Position | 12 O' Clock |

| Welding Wire Size | φ1.2-1.6 mm |

| Welding Power Supply | 500 A, 250 KVA |

| Welding Swing Range | 0 ~ 35 mm |

| Welding Swing Unit Voltage Range | 95 ~ 250 V |

| Total Power | 4 kW |

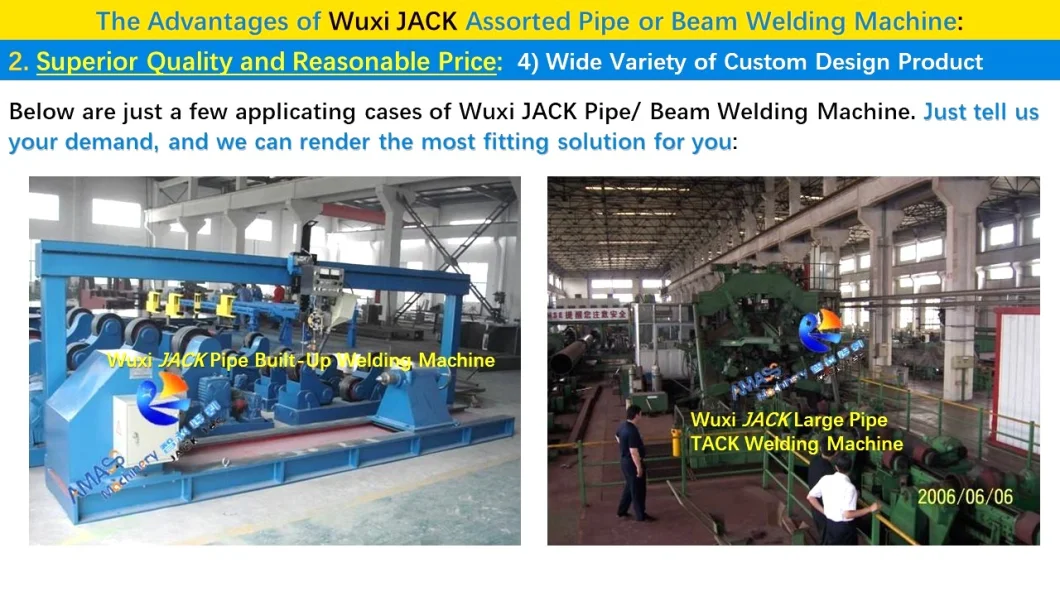

3. Heavy duty Automatic Pipe Tack Welding Machine: (Fig.3)

1) Usage: For CO2 tack welding on Oil Gas Pipeline2) Technical Parameters: 4. Large Pipe Internal Longitudinal Welding Machine: (Fig.4)

1) Usage: For internal SAW welding on Oil Gas Pipeline2) Technical Parameters: 5. Longitudinal Seam Welding Machine: (Fig.5)

1) Usage: For longitudinal seam welding inside thin wall pipes2) Technical Parameters: 6. Gantry Frame Submerged Arc Welding Machine: (Fig.6)

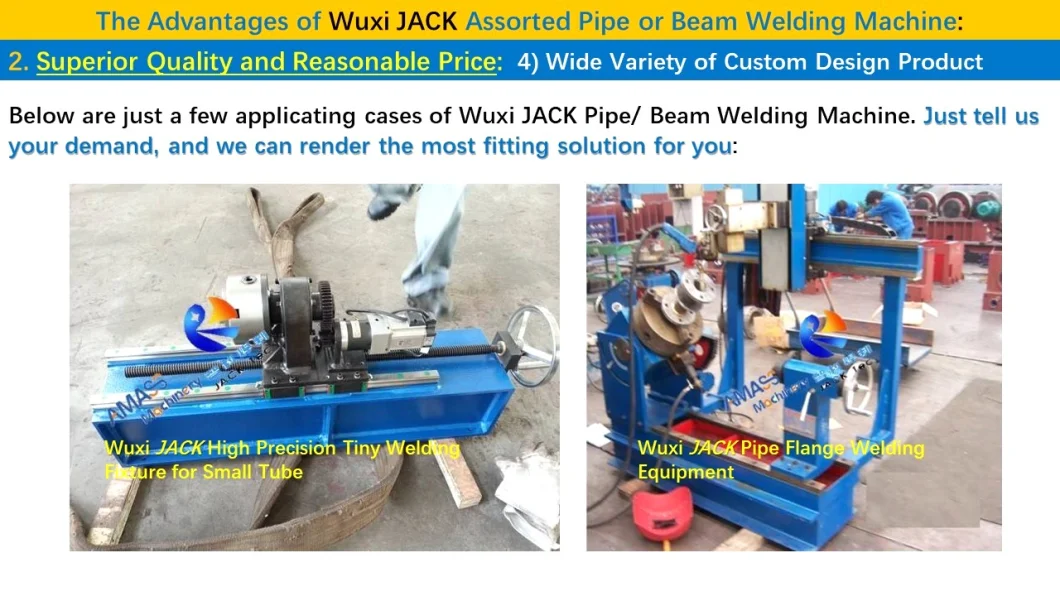

1) Usage: For SAW on large size workpieces2) Technical Parameters: 7. High Precision Portable Special made Welding Positioner: (Fig.8)1) Usage: For laser welding on small tubes;2) Technical Parameters: Depends on specific application

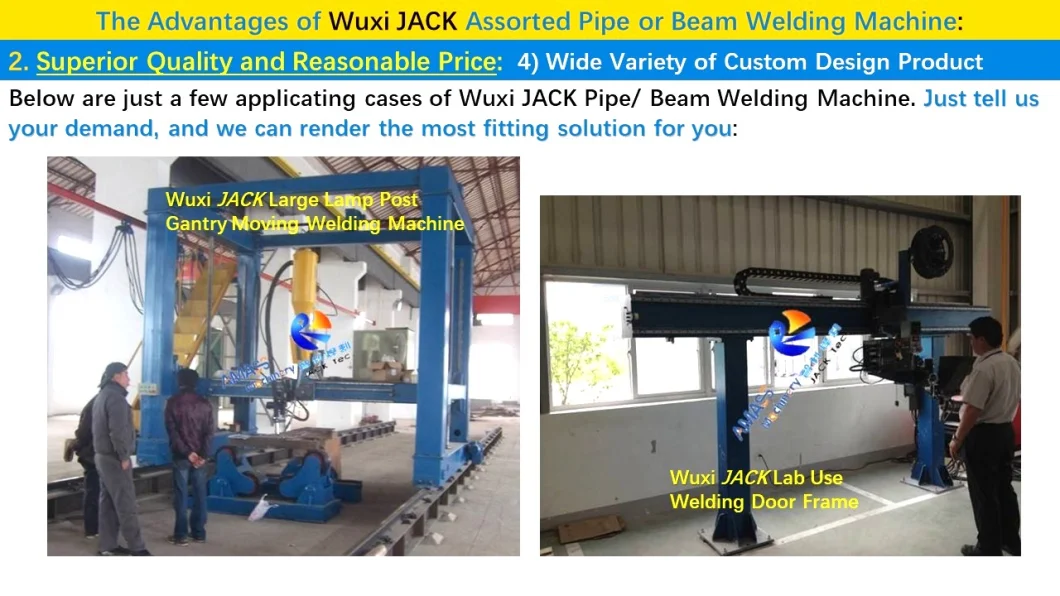

8. Special made Gantry Frame Welding Machine: (Fig.9)

1) Usage: For validating welding technology in lab2) Technical Parameters: Depends on specific application 9. Custom made Circumferential Welding Machine: (Fig.10)

1) Usage: Circumferential welding for Pipe Flange;2) Technical Parameters: 10. Tailor made Circumferential Welding Machine: (Fig.11)

1) Usage: Circumferential welding for Small Flange2) Technical Parameters: 11. Special made Circumferential Welding Machine: (Fig.12)1) Usage: Circumferential welding for Small Cylinder Body2) Technical Parameters: Depends on specific application

12. Automatic Girder Longitudinal Welding Machine: (Fig.13)

1) Usage: Longitudinal welding on long BOX Beam2) Technical Parameters: 1. Q: What is the relationship between Wuxi AMASS and Wuxi JACK? A: Wuxi AMASS and Wuxi JACK are the same company: Wuxi AMASS is wholly owned subsidiary of Wuxi JACK, for overseas trading Wuxi JACK products;

2. Q: What is the nature of your company? A: Business scope of Wuxi JACK and AMASS covers design, production and selling;

3. Q: What is the range of your company product? A: Wuxi JACK and AMASS is a professional supplier in Welding and Cutting Industry;Main products of our company include:1) Steel structure production equipment (H Beam/ BOX Beam/ T Beam);2) Edge Milling Machine;3) Structure member Beam end face milling machine;4) CNC Plate Cutting Machine;5) CNC Pipe Cutting Machine;6) Various kinds of conventional and special design welding equipment and machine;7) Various kinds of conventional and special design Straightening machine, etc.;

4. Q: What is the strength of your company? A:1) Wuxi JACK was founded by 3 senior engineers 15 years ago;2) Engineering team of our company has over 20 years experience on Welding and Cutting industry;3) Operation manager has 14 years experience working in an American Fortune Global 500 Dow Jones Industrial Index Company as senior Project Manager;4) The competitive edge of our company is special design products based on customer demand.

5. Q: What are service terms of your company? A:1) During business negation: a) Make technical proposal and quotation;b) Answering customer questions;c) Make final contract and technical agreement;2) During order to delivery value chain:a) Design, validate, and manufacture products for customers;b) Inform progress of manufacture to customers;c) Arrangement for package and shipment of products to customers;3) After sale service: a) Technical support on installation and commissioning at customer site;b) 1 year guarantee from the date of acceptance;c) Feedback any technical issues within 4 hours upon getting the notice;

6. Q: Where is location of your company? A: Wuxi city, Jiangsu province, 130km from Shanghai

Our Contact

Send now