Manual Automatic Poly Hydraulic Butt Fusion Plastic PE Pipe Hot Melt Welding Machine HDPE Pipe Welder

Description

Basic Info.

| Model NO. | JS-63-160 |

| Operating Temperature | 220degrees Celsius |

| Total Power Consumption | 1.7kw /220V |

| Welding Temperature Required Time | 20min |

| Weldable Material | PE PPR Pb PVDF |

| Ambient Temperature | -5-40 Degrees Celsius |

| Welding Specification | 160 |

| Temperature Error | 3degrees Celsius |

| Docking Deviationate | 0.3mm |

| Work Form | Spot Welding |

| Name | Hot Fusion Butt Welding Machine |

| Transport Package | Wooden Case |

| Specification | 1.7KW /220V |

| Trademark | JIESHENG |

| Origin | Shandong, China |

| Production Capacity | Other |

Product Description

Product DescriptionManual automatic poly Hydraulic Butt Fusion plastic PE Pipe hot melt Welding Machine HDPE Pipe Welder

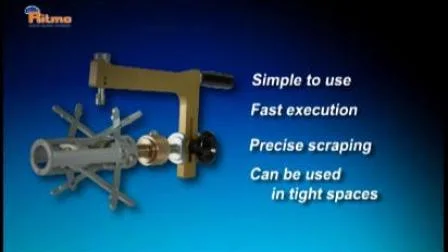

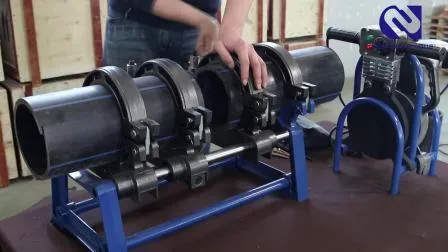

This machine is suitable for thermoplastic pipes and fittings made of PP PB PVDF operating on the ditch or construction site.Comconsists of rack, milling cutter, heating plate and accessory bracket.Made from a lightweight, high-strength material.Save the labor force and work efficiently.The main parts of the machine are made of pure aluminum, which is lighter, strong and smooth than turning sand and steel mold.

Detailed PhotosProduct Parameters

| model | 63-160 | 63-200 | 90-250 |

| Welding specifications | 63,75,90,110,125,140,160 | 63,75,90,110,125,140,160,180,200 | 63,75,90,110,125,140,160,180,200,225,250 |

| Docking deviation | ≤0.3mm | ≤0.3mm | ≤0.3mm |

| temperature error | ±3°C | ±3°C | ±3°C |

| Total power consumption | 1.7kw/220V | 2.3kw/220V | 3.15kw/220V |

| working temperature | 220°C | 220°C | 220°C |

| ambient temperature | From sub-5-40ºC | From sub-5-40ºC | From sub-5-40ºC |

| Time required to reach the welding temperature | <20min | <20min | <20min |

| Welding materials | PE PPR PB PVDF | PE PPR PB PVDF | PE PPR PB PVDF |

1. 24 hours on line service, support Chinese, English, Spanish, French, German, Russian ,technical guidance.2. When meets machine failure problem, our factory will ensure that the problem is solved within 1 hour.3. Povide machine install video.4. Provide logistics information, like shipping by sea, shipping by express DHL, FEDEX delivery, real-time tracking service.5. If machine is broken ,Non-human causes,the new machine will be provided or new parts will be provided.

FAQAre you manufacture?Yes. We are one of leading manufacturersDo youhave Stockproductions to sell?Yes,ofcourse.Butwe also offer OEM service. Please send us some drawing.What information do you want to know if i want to get a quotation?a). The model/size of your products. b). The application for your products. c). Special package methods if you needs. d). Raw material.Do you inspect the finished products?Yes.Each step of products will be carried out inspection by QC department until shipping What advantages do you have?(1) Punctual: Have your orders met with the latest delivery?We are a manufacturer with so many advanced and new machines. It ensures we have the ability to carry out the production schedual for punctual delivery.(2) 20year production experience. We have over 20 years exprerience in this industry.That means we can preview the problems for the orders and production. Therefore, it will make sure to deduce the risk of bad situation to happen.(3) Point to point service.There is two sales departments who will serve you from inquiry to products shipped out. During the process, you just need to discuss with him for all the problems and the way sames much times

Next: Manual 63

Our Contact