Welping 315

Description

Basic Info.

| Model NO. | WP630A |

| Overall Power | 10.1kw |

| Heating Plate | 7.5kw |

| Pressure Adjusting | 0-8MPa |

| Hydraulic Station | 1.1kw |

| Volume | 2.415cbm |

| Planing Tool | 1.5kw |

| Max Temperature | 270ºC |

| Temperature Deviation | ±7ºC |

| Heating Plate Surface Temperature | 170ºC-250ºC |

| Power Supply | 380V 50Hz |

| Applicable | PE, PP, PVDF |

| Transport Package | Plywood Case |

| Specification | O. D. 315-630mm |

| Trademark | welping |

| Origin | China |

| HS Code | 8515809090 |

| Production Capacity | 20000sets/Year |

Product Description

| Model | WP630A | ||

| Suitable materials | PE, PP, PVDF | ||

| Range | 315-355-400-450-500-560-630mm | ||

| Power supply | 380V ,3PH | ||

| Frequency | 50 Hz | ||

| Total power | 10.5 KW | ||

| Heating plate | 7.5 KW | ||

| Planing tool | 1.5KW | ||

| Hydraulic station | 1.1KW | ||

| Max.Temperature of heating plate | 270ºC | ||

| Pressure gauge | 16Mpa | ||

| Pressure range | 0-8.0Mpa | ||

| Temp.Deviation in Surface | ±7ºC | ||

| Total Weight | 560kg | ||

| Net weight | 475kg | ||

| Basic Frame | plywood case | 1540*930*990 1.418CBM | |

| Hydraulic station | plywood case | 670*560*720 0.270CBM | |

| planing tool & heating plate | plywood case | 930*620*1260 0.727CBM | |

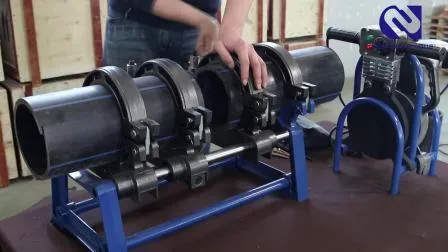

-Complete welded steel structure, strong, free of distortion-Sturdy steel clamping parts with complex reinforced structure-Balanced upper and lower clamping sets, for easy pipe tightening operation-Separate actuation hydraulic cylinder design, for easy installation & maintenanceHeating Plate.

-Cast aluminum body with Anti-stick PEFT coating from Dai kin -Qualified built-in heating elements, swift and steady temperature rising -Standard equipped with aviation plug and heavy duty cable, ensures operation safety Trimmer.

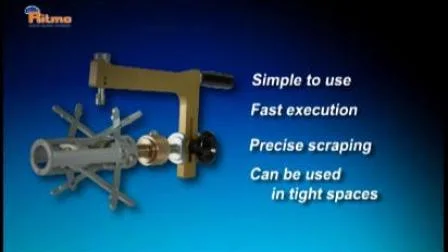

-Reinforced trimming plate, anti-crack-Powerful copper-wiring motor -Durable, double edges HSS blade

Hydraulic Power Station.

-Integrated hydraulic and electrical control, for easy operation access -All-in-one control panel: hydraulic actuation, pressure setting, timing, electric info display, temperature setting-Enclosure design, shielding splash and dirt and wheels, for easy transportation

| S/N | Model | Standard Welding Range (mm) | Optional Reducers (mm) | Power Supply |

| 1 | WP160A | 63-75-90-110-125-140-160 | 220V-50Hz | |

| 2 | WP200A | 63-75-90-110-125-140-160-180-200 | 220V-50Hz | |

| 3 | WP250A | 90-110-125-140-160-180-200-225-250 | 63-75 | 220V-50Hz |

| 4 | WP315A | 90-110-125-140-160-180-200-225 -250-380-315 | 220V-50Hz | |

| 5 | WP355A | 160-180-200-225-250-380-315-355 | 110-125-140 | 220V-50Hz 380V-50Hz |

| 6 | WP400A | 180-200-225-250-380-315-355-400 | 380V-50Hz | |

| 7 | WP450A | 200-225-250-380-315-355-400-450 | 180 | 380V-50Hz |

| 8 | WP500A | 250-380-315-355-400-450-500 | 180-200-225 | 380V-50Hz |

| 9 | WP630A | 315-355-400-450-500-560-630 | 380V-50Hz | |

| 10 | WP800A | 630-710-800 | 450-500-560 | 380V-50Hz |

| 11 | WP1000A | 800-900-1000 | 560-630-710 | 380V-50Hz |

| 12 | WP1200A | 1000-1100-1200 | 800-900 | 380V-50Hz |

| 13 | WP1400A | 1000-1200-1400 | 380V-50Hz | |

| 14 | WP1600A | 1200-1400-1600 | 380V-50Hz |

1. Payment

We accept 30% TT deposit and 70% balance payment before delivery or 100% TT in advance.

2. Lead time

Standard items and light-OEM items, WELPING can finish in around 10-15 days.

3. Warranty

18months from delivery date. We take full responsibility for parts with quality problems and provide them for free.

4. Customized design

Our experienced technical team can develop different solutions according to customers. MOQ is required for special requirements.

5. About agency business

We welcome sincere and influential customers to discuss cooperation matters with us.

Prev: Root Pass Pipe Automatic Welding Machine (FCAW/GTAW)

Next: Manual Heat Fusion Pipe Welding Machine for PE/PPR/Pb/PVDF Pipe

Our Contact